The design and construction of tooling represent both the critical path and the greatest capital expenditure in the development of a new product. Ocean5’s expertise in the design and construction of tooling can bring your new product to market faster and ensure your capital outlay will yield high-quality, precise, and durable tooling. Ocean5 is well-versed in the latest technologies in plug and mold production and can help to efficiently put these to work in your new product development process.

Choosing the right construction technique is a key element to the successful development of all projects. We can leverage technology, labor, and time to create a cost-effective solution that works for the builder. While jig-kit construction is a common method for custom one-off construction, it can also be employed to create plugs and molds, both large and small. Depending on the complexity of the part, several techniques can also be combined together. In this way, small detailed areas can be 5-axis milled as blocks and integrated into the overall jig design.

Other methods include layered and stacked 2-D CNC geometry which can be indexed & dowelled together. Ocean5 has experience in both custom and production boatbuilding, as well as strong working relationships in the industry, to develop a customized solution for your next project.

Mock-ups

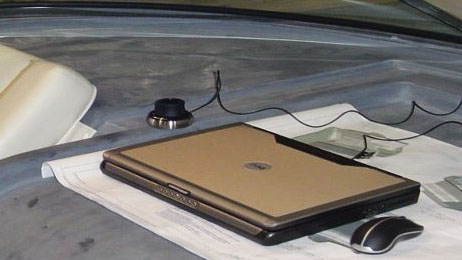

Simple solutions that leverage computer model data already developed can prove invaluable to the shop floor. Whether it’s full-size floor layouts printed on Velum for virtual walk-throughs before construction to validate arrangements or cut files for production, we have the resources to provide the technical support you need.

Full-Size Paper Patterns